Large manufacturers in the industry choose HUANUO; high standard manufacturing, to meet the stringent technical requirements.

PRODUCTProduct classification

Business consulting

![]()

HN-7000 series full-automatic PCBA board cleaning machine; is an online full-automatic PCBA board special cleaning machine, which is suitable for traditional board washing water without manual contact with cleaning agent. This equipment combines PCBA boar

HN-7000 series full-automatic PCBA board cleaning machine; is an online full-automatic PCBA board special cleaning machine, which is suitable for traditional board washing water without manual contact with cleaning agent. This equipment combines PCBA board transmission technology and brush cleaning technology. Combined, multiple brushing in all directions, front and back, left and right, clean without dead ends, to ensure that the PCBA board meets the cleanliness requirements. It is suitable for cleaning the soldering surface of single-sided PCBA board without wetting the front components.

ØThis machine has a unique body structure, stable performance, and the highest cleaning effect in the industry.

ØSpecially used for the cleaning of tin beads, flux traces and scratches.

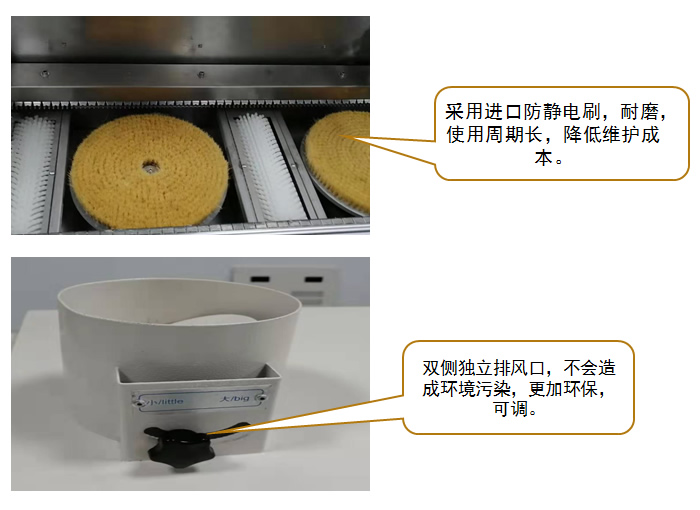

ØImported brown hair brush, anti-static brush, will not generate static electricity, will not harm the PCBA board.

ØSuitable for PCB boards with board edges, (the board edge distance is at least 1.5mm), and the PCBA board can adapt to the width range.

ØThe thickened shrapnel claw ensures that the PCBA board will not shift during transportation.

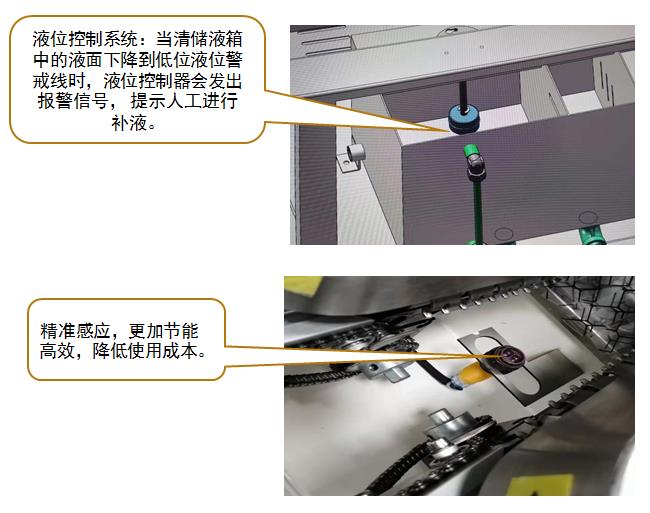

ØCleaning agent automatic coating system: to ensure that the welding surface of the PCBA board can be evenly coated with washing water without affecting the surface of other parts.

ØDisc brush + two rollers: to ensure that the PCBA board is clean in all directions without dead ends.

ØThe height of the cleaning brush and the rotation speed (infinitely variable) can be adjusted to meet different cleaning needs.

ØThe waste generated by the work is automatically collected in the filter box at the lower part of the machine for easy cleaning.

ØIt is driven by high-quality electronic speed regulating motor, and the motor speed is steplessly adjustable, which is durable.

ØUse 220V power supply, easy to use.

ØAdopt brand electric appliances and control system to ensure the reliability and stability of the control system.

ØUsing modular control.

|

Model number: |

HN-FR-7000 |

HN-FR-7100 |

HN-FR-7200 |

|

Maximum size of PCBA board: |

200mm(L) x 200mm(W) |

300mm(L) x 300mm(W) |

550mm(L) x550mm(W) |

|

External dimensions: |

L1750*W670*H980±2mm |

L1750*W770*H980±2mm |

L2150*W970*H980±2mm |

|

Coating drum size: |

φ100mm |

φ100mm |

φ100mm |

|

Disc brush size: |

φ200mm |

φ320mm |

φ550mm |

|

Spindle speed: |

0-500 rpm (adjustable) |

0-500 rpm (adjustable) |

0-500 rpm (adjustable) |

|

Operating Voltage: |

220V/50HZ |

220V/50HZ |

220V/50HZ |

|

Total power: |

0.9 (KW) |

1 (KW) |

2.2 (KW) |

|

Transmission speed: |

0.05~1.8m/min (infinitely variable speed) |

0.05~1.8m/min (infinitely variable speed) |

0.05~1.8m/min (infinitely variable speed) |

Control mode: divided into two types of "manual operation/automatic operation"

①Manual operation mode: each system function can be completed manually one by one

②Full automatic operation mode: When there is no PCBA board in the machine, the system will make a judgment. At this time, the brush will be cleaned and the water pump will enter the stop state. The cleaning fluid circulation system enters a fully enclosed state.

|

Item |

Process name |

Cleaning introduction |

Cleaning time |

Cleaning method |

Cleaning box |

|

1 |

Primary cleaning |

detergent |

Adjustable |

Roller brush (white) |

custom made |

|

3 |

Secondary dry cleaning |

Dry |

Adjustable |

Disc brush (brown hair) |

custom made |

|

4 |

Three-level cleaning |

detergent |

Adjustable |

Roller brush (white) |

custom made |

|

5 |

Level 4 dry cleaning |

Dry |

Adjustable |

Disc brush (brown hair) |

custom made |

1. Commitment: Warranty period: 1 year, lifetime maintenance. Response time: After receiving the user's notice, professional and technical personnel will not exceed 24 hours (local) and 48 hours (off-site) on-site service to ensure 24-hour uninterrupted after-sales technical service support; repair time: 48 hours.

2. Free warranty: Free warranty during the warranty period, and after the warranty period, spare parts and maintenance services are guaranteed at a reasonable price.

3. Free training: On the day of training, the purchaser’s technical personnel will be trained on the equipment operation for free to ensure that the user’s personnel can be proficient in conventional use methods such as various equipment and software, as well as the judgment and resolution of minor faults.

简体中文

简体中文 English

English Contact us

Contact us