Large manufacturers in the industry choose HUANUO; high standard manufacturing, to meet the stringent technical requirements.

PRODUCTProduct classification

Business consulting

![]()

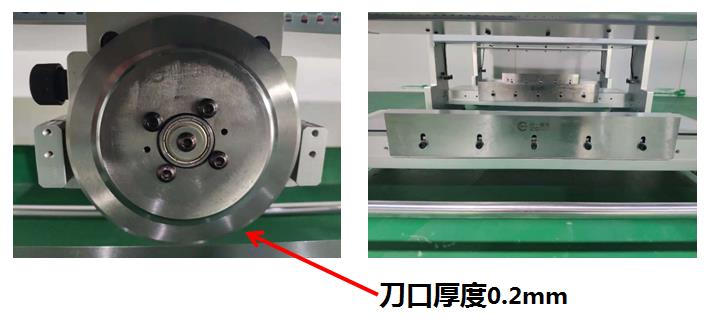

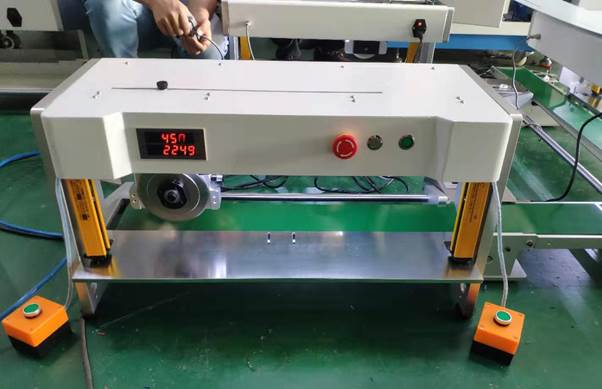

HN-208 double-travel splitting machine adopts the design of the upper circular knife and the lower straight dao. When cutting the board, the v-cut is placed on the lower straight dao, the circuit board does not move, and the upper round dao moves the cutt

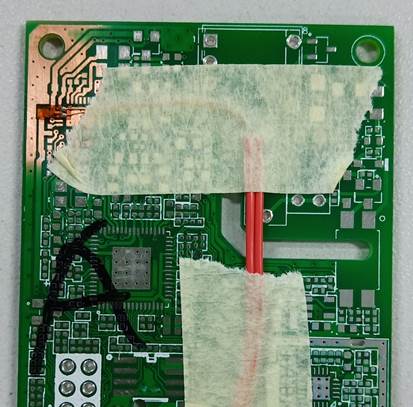

HN-208 double-travel splitting machine adopts the design of the upper circular knife and the lower straight dao. When cutting the board, the v-cut is placed on the lower straight dao, the circuit board does not move, and the upper round dao moves the cutting board, the stress is relatively small. The cutting board mode of the board not moving and moving also effectively avoids bumps during the circuit board splitting operation, and avoids problems such as dark injuries and component damage.

It is suitable for various glass fiber boards, FR-4 boards, FR-1 boards, etc., relatively harder than aluminum substrates and other large substrates. For PCB boards with components on both sides, this equipment is especially suitable for sub-boarding.

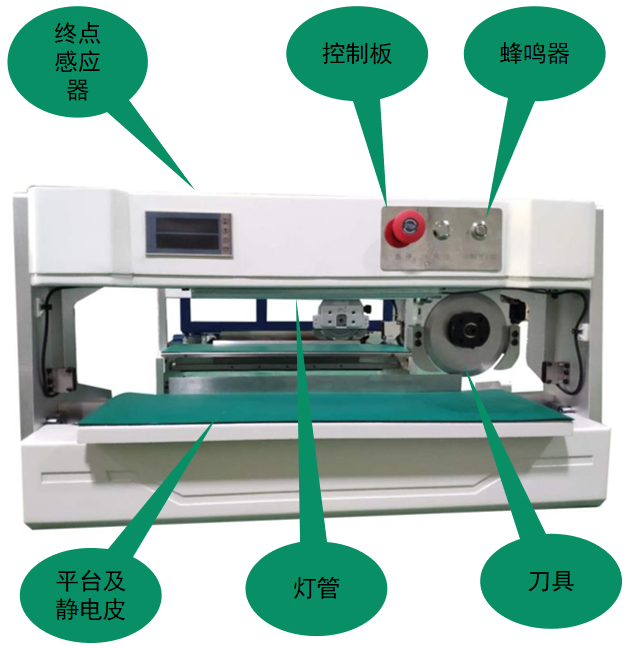

1. Steel: The upper and lower cutters are imported high-speed steel SKD11, and the cutting times can reach one million.

2. Lamp tube: the operator's work is more convenient and the field of vision is wider.

3. Buzzer: rationalize safe operations and improve operator safety awareness.

4. Control panel: adjust the knife speed and record the number of cutting boards.

5. Cutting stroke: The end sensor stroke is the cutting stroke, and the range is 0mm-600mm. (Itinerary can be customized 600-1200MM)

6. Platform and electrostatic protection device: The height of the lifting platform can be adjusted reasonably according to the product, and the electrostatic skin can increase the electrostatic protection function.

1. Moving knife split type, the stress of split plate is relatively small.

2. A conveyor belt is installed to transport the divided PCB board to the production line.

3. The single-chip microcomputer controls the knife, which is easy and convenient to operate.

4. Safety: With double protection devices, there is no need to worry about production safety issues.

5. Easy to use: Simple operation, and can be used proficiently without training.

6. Durable: It is made with the best materials and the exclusive craftsmanship of vulnerable parts and knives are durable.

7. It is suitable for cutting all kinds of PCB boards with components on both sides.

| project | HN-208 |

| name | PCB cutting board splitter |

| Dimensions L/W/H | L900mm×W450mm×H420mm |

| Tool size | Round knife ϕ125mm×12mm×3mm Straight knife ϕ600mm×65mm×6mm |

| Tool material | Imported high-quality high-speed steel |

| Tool brand | Huanuo |

| Sub-board thickness | One-third thickness |

| Sub-board length | 5mm-600mm long |

| Splitting speed | 300mm-500mm/s (speed adjustable motor, adjustable speed) |

| Sub-board width | 1mm-200mm is the best (small piece width, non-integrated width), integrated width 250mm |

| working pressure | no |

| Operating Voltage | 220V/110V optional |

| equipment power | 100W |

| Total Weight | 75kg |

1. Tool material: imported SKD11 high-speed steel

2. Tool brand: CAB

3. Tool size:

Round knife: ϕ125mm×12.5mm×3mm

Straight knife: ϕ420mm×65mm×6mm

Note: The blade has a service life of 4 million times and can be re-ground and reused. The blade depends on the situation, and it can be re-ground 2-3 times.

|

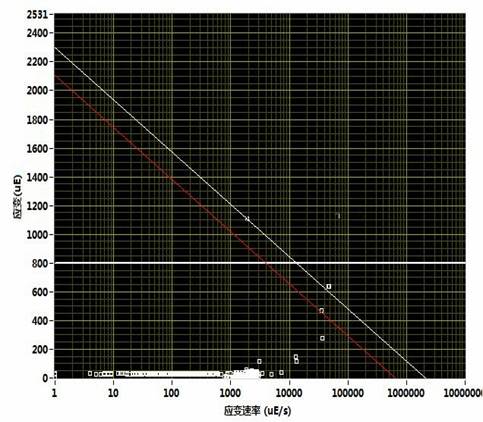

IPC9704 form |

|

|

|

|

|

|

Numbering |

Component name |

Cutting speed |

Maximum strain (uE) |

Maximum strain rate (uE/s) |

result |

|

|

|

|

|

|

|

|

No.1 |

a |

15mm/s |

-634 |

-176777 |

PASS |

1. Docking production line: products can directly flow into the assembly line, and follow-up operations of docking products;

2. The operation is more convenient: the product flows into the back end, and the operator does not need to take the board repeatedly after dividing the board;

3. The degree of automation is higher, and it is more suitable for production lines with higher automation;

Product customization:

1. The main carrier is the same: customized products rely on the existing knife to make customized changes;

2. Customization: a higher degree of automation adaptability, more and more satisfying and fulfilling customer needs

1. Plug in the power and turn on the power switch on the device.

2. Adjust the gap between the upper round knife and the lower straight knife.

3. Put the V-CUT groove of the product on the edge of the lower straight knife.

4. Step on the foot switch to start the machine.

5. Put the divided products into the material frame, or flow into the conveyor belt to connect to the production line.

6. The machine completes a work process.

1. Commitment: Warranty period: 1 year, lifetime maintenance. Response time: After receiving the user's notice, professional and technical personnel will not exceed 24 hours (local) and 48 hours (off-site) on-site service to ensure 24-hour uninterrupted after-sales technical service support; repair time: 48 hours.

2. Free warranty: Free warranty during the warranty period, and after the warranty period, spare parts and maintenance services are guaranteed at a reasonable price.

3. Free training: On the day of training, the purchaser’s technical personnel will be trained on the equipment operation for free to ensure that the user’s personnel can be proficient in conventional use methods such as various equipment and software, as well as the judgment and resolution of minor faults.

简体中文

简体中文 English

English Contact us

Contact us