Large manufacturers in the industry choose HUANUO; high standard manufacturing, to meet the stringent technical requirements.

PRODUCTProduct classification

Business consulting

![]()

It is suitable for batch die-cutting of circuit boards of mobile phones, digital cameras, computers, automobiles, etc., when cutting multi-connected circuit boards, LED light boards, etc., it can exert the greatest effect.

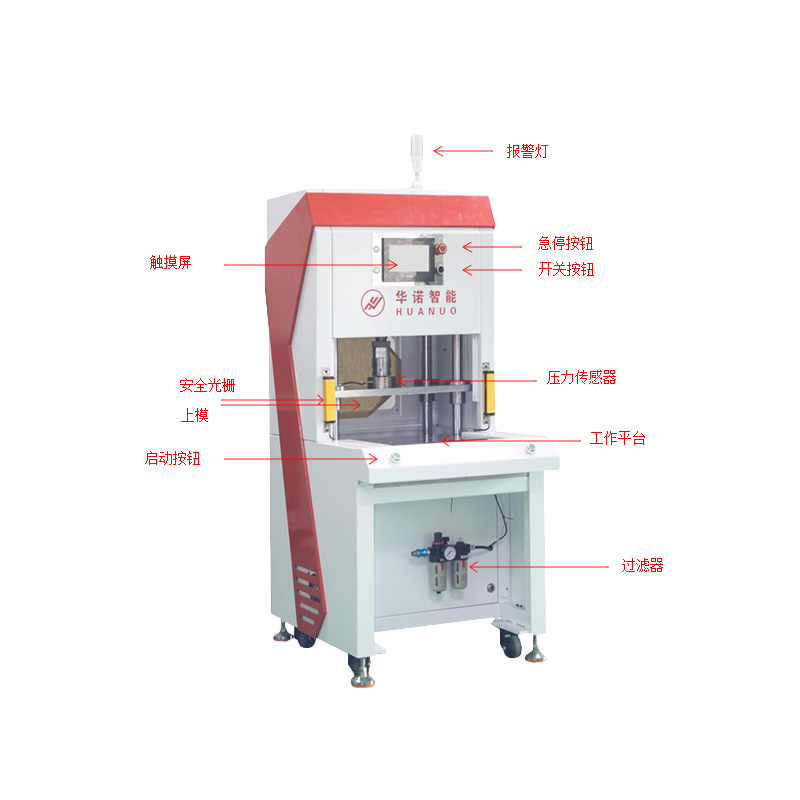

The HN-C3-8T punching and splitting machine has a compact and firm structure, air cylinder output, no pollution to the environment, large output, and simple operation.

It adopts the latest gas-electric lightweight design and can use various knife molds.

Effectively cut various FR4, aluminum base hard circuit boards and flexible printed circuit soft boards.

It is suitable for batch die-cutting of circuit boards of mobile phones, digital cameras, computers, automobiles, etc., when cutting multi-connected circuit boards, LED light boards, etc., it can exert the greatest effect. Pressurized by a pressurized cylinder drive.

Features of cutting FPC substrates by punching:

1. High efficiency: 6 to 8 puzzles can be divided into one minute.

2. High quality: The surface of the slitting product is flat and uniform in size.

3. High environmental protection: low noise and dust-free production, thereby reducing environmental pollution.

4. Low energy consumption: the main power is air power.

5. Low intensity: Greatly reduce the labor intensity of employees.

Sixth, easy to operate: easy to operate, new or old employees are easy to learn, easy to learn and easy to operate.

Seven, high safety: the automatic entry and exit mode of the lower die is adopted for slitting, and there are gratings and safety doors to protect the operator and operate more safely.

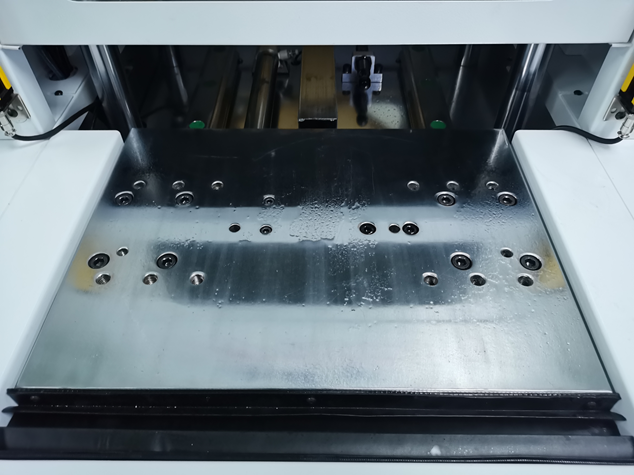

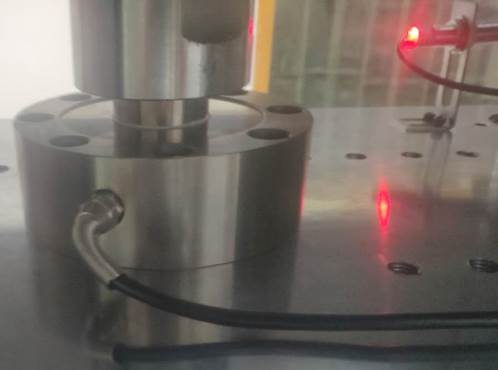

Partial view of mechanical cylinder

Machine details display

Workbench: used for the operator to take and place products, take the punched products, and place the products to be cut;

Safety grating: to prevent operators from misoperation and place their hands and other tools in the work area to protect employees' safety;

Double start button: foolproof and safety protection function to prevent misoperation by employees and accidental touch by non-workplace operators;

8T mechanical cylinder: meets 0-8T pressure adjustable, can adapt to more kinds of products.

Pressure sensor details display

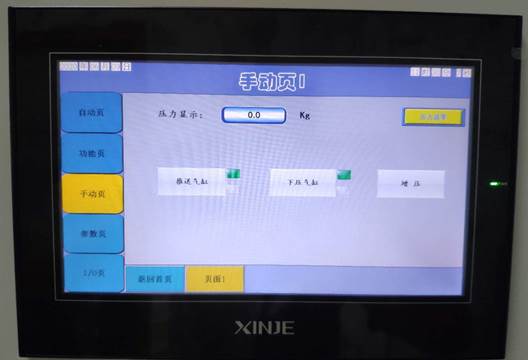

Touch screen display

Pressure sensor: It can sense the punching pressure when punching the product, and provide a more accurate punching pressure value for the operator to better adjust the basis;

Touch screen: set operating authority, control: jog, manual, semi-automatic, output storage, statistics and error information storage parameter settings (engineer: need to set permissions) to select and set each station of the program, real-time monitoring, parameter settings and other functions

|

Equipment appearance specifications |

Machine name |

FPC stamping machine |

|

machine type |

HN-C3-8T |

|

|

Dimensions |

Length * width * height: 900*630*1700mm |

|

|

shape |

Floor-standing |

|

|

weight |

500KG |

|

|

colour |

Computer white |

|

|

Equipment supply requirements |

power supply |

AC220V |

|

Environmental requirements |

Clean and dry, avoid humidity or high temperature |

|

|

Working pressure/pipe diameter |

> 0.6MPa/ > 10mm |

|

|

Minimum distance between part and cutting position |

≧ 0.5mm |

|

|

Maximum sub-board length |

260*320mm (can be customized for larger area) |

|

|

FPC cut point location |

No components are allowed to cross above the tangent point |

|

|

Positioning hole requirements |

There are at least four positioning holes on the FPC, plus one foolproof hole |

|

|

Maximum height of FPC board components |

For PCB parts, the height limit is 30mm, and the front height limit is 35mm |

|

|

Device software part |

Controller PLC |

Xinjie |

|

parameter settings |

The punching value can be set through the touch screen |

|

|

Storage module |

Can store multiple sets of data |

|

|

operating system |

Independent research and development operating system |

|

|

touch screen |

Xinje touch screen PLC controller supporting touch screen |

|

|

Stress Sensing Module |

sensor |

|

Mould |

Mold properties |

High speed steel |

|

Mold type |

Knife mold or precision steel mold/composite mold |

|

|

Blade angle |

According to customer product cutting point design |

|

|

Service life |

2 million times |

|

|

Making mold information |

Product Gerbar or CAD file and 2-5 pieces of finished board |

|

|

Change time |

10min |

|

|

Production cycle |

10 days |

|

|

Mold accuracy |

0.05mm |

|

|

Main control slitting system |

Sub-board efficiency |

8-12s a whole puzzle |

|

Guide screw |

Shanghai Bank |

|

|

Pneumatic accessories |

AirTAC |

|

|

Equipment output |

8/10/15/20/30/60 tons output |

|

|

Way in and out of the board |

Cylinder guide rail or servo system + screw guide rail |

|

|

Other functions |

Protection function |

Light barrier, sensor and software triple protection two-hand button start |

|

Surface treatment of machine parts |

Anode, electroplating |

|

|

Punching method |

Mechanical cylinder, high-speed pressurized cylinder, hydraulic cylinder |

|

|

Security |

Safety door grating, emergency stop switch |

|

|

Self-check function |

Boot time monitoring, capacity monitoring, equipment failure information and automatic rejection system |

|

|

Scope of application |

Suitable for slitting FPC board with components, stamp hole PCB or aluminum substrate, copper substrate |

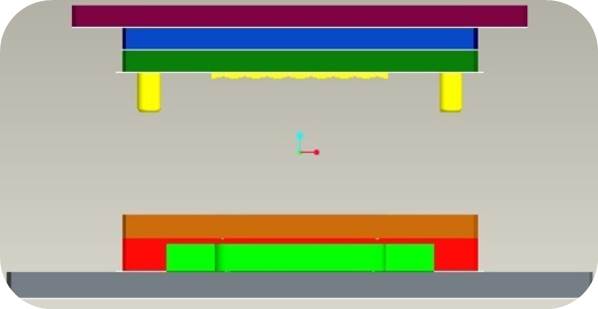

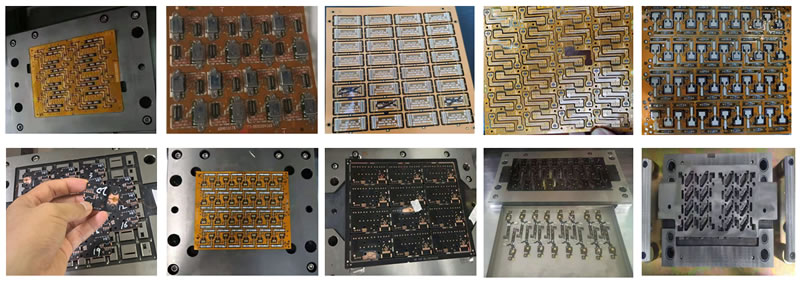

Mold front view

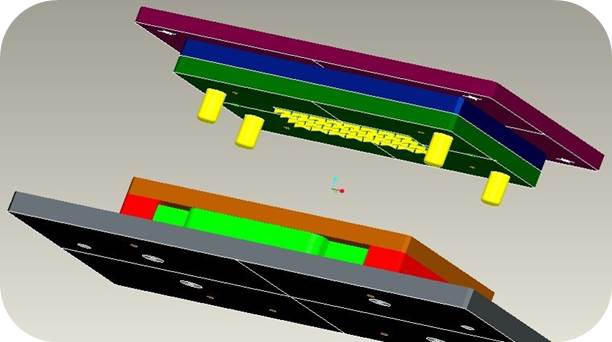

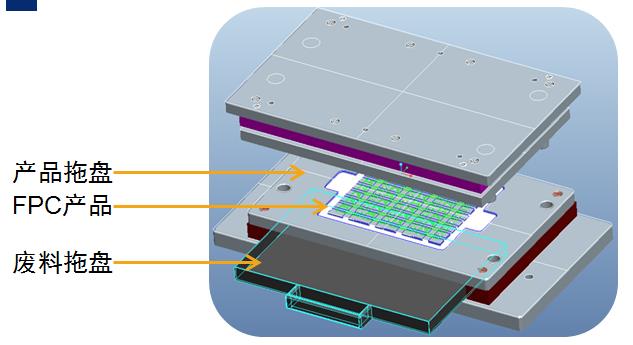

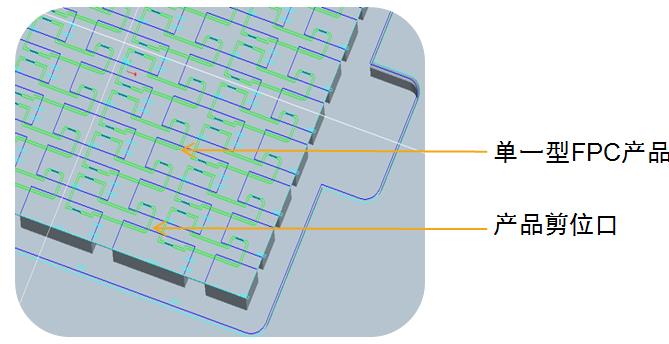

Mold parting diagram

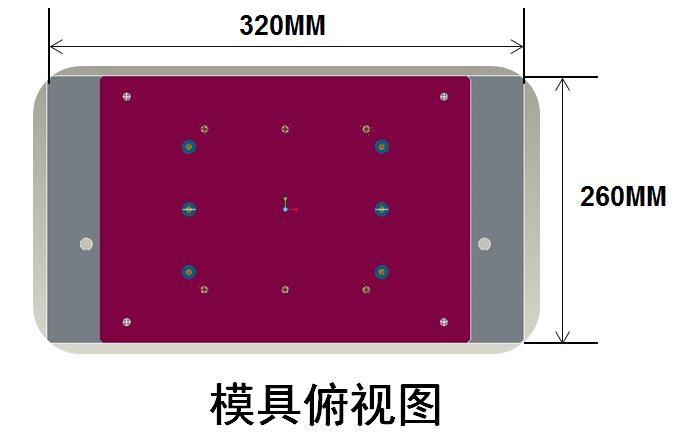

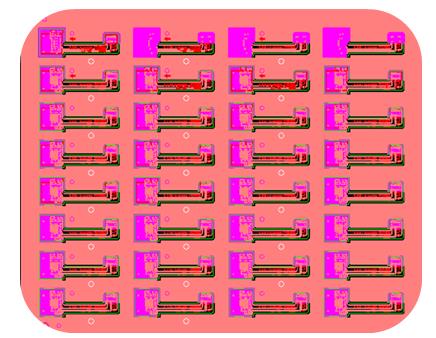

Mold size: The mold size of this machine is 260MM*320MM, other products or needs can be customized according to requirements;

Guide post: play a role in positioning the guide port to ensure the precise cutting position of the product.

Product tray: customized according to customer product requirements

Demolition of waste edges:

For the stripping of bridge-connected PCBs, the scrap edges are usually removed manually, because the scrap edges are relatively large. Similarly, FPC products are also manually removed.

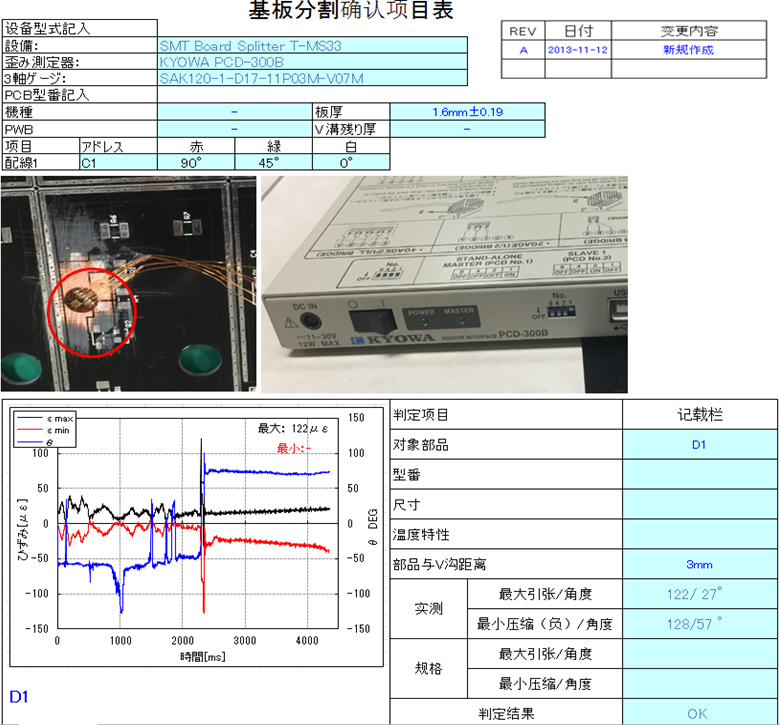

Pressure tester

Customer's 1.6MM thick FPC board pressure test

1. Commitment: Warranty period: 1 year, lifetime maintenance. Response time: After receiving the user's notice, professional and technical personnel will not exceed 24 hours (local) and 48 hours (off-site) on-site service to ensure 24-hour uninterrupted after-sales technical service support; repair time: 48 hours.

2. Free warranty: Free warranty during the warranty period, and after the warranty period, spare parts and maintenance services are guaranteed at a reasonable price.

3. Free training: On the day of training, the purchaser’s technical personnel will be trained on the equipment operation for free to ensure that the user’s personnel can be proficient in conventional use methods such as various equipment and software, as well as the judgment and resolution of minor faults.

简体中文

简体中文 English

English Contact us

Contact us