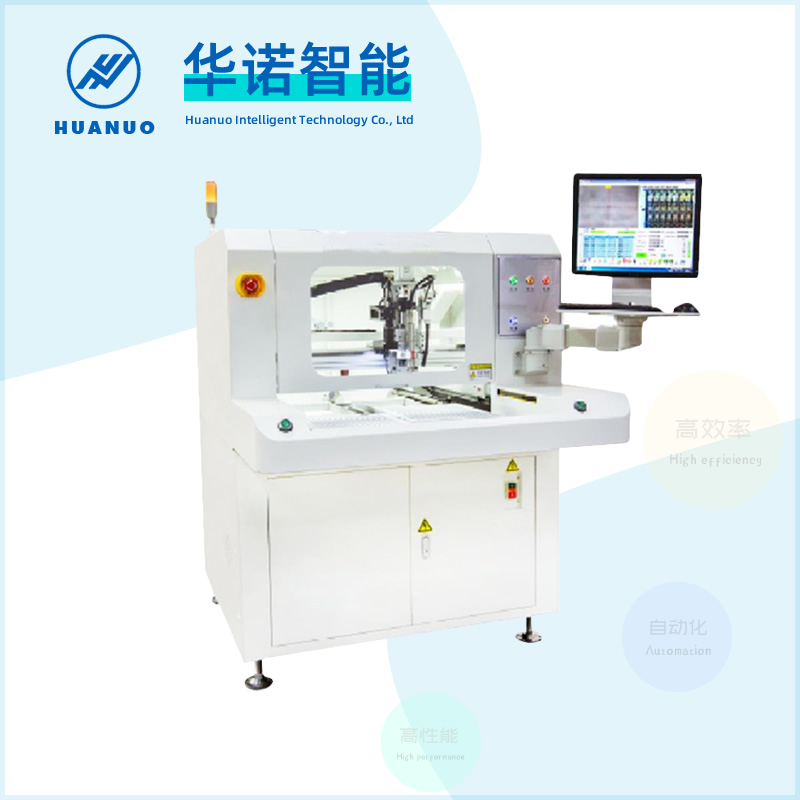

Large manufacturers in the industry choose HUANUO; high standard manufacturing, to meet the stringent technical requirements.

PRODUCTProduct classification

Business consulting

![]()

With the continuous development of the electronics industry, the production requirements for the substrates, which are important components of electronic products, are becoming higher and higher, and they are developing towards high precision, high densit

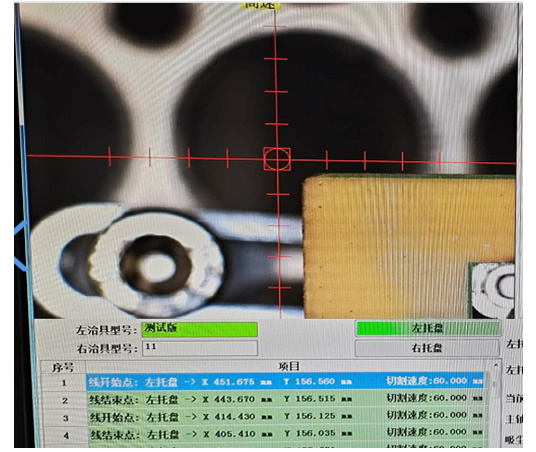

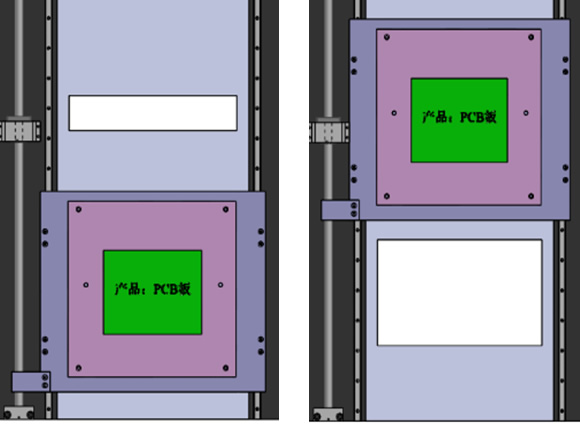

1. Change the traditional geometric patterns that can only recognize circles, squares, etc. Can recognize any shape marking point;

2. Not only has the function of error correction and fool prevention, but also can calibrate the data, so there is no need to worry about employees putting the wrong board;

3. The displacement function can realize the arbitrary placement of the fixture on the worktable.

1. Change the traditional segmentation mode;

2. Adjust the cutting depth according to the thickness of PCB, increase the utilization rate of milling cutters and save costs;

3. The condition of the milling cutter can be defined according to the needs of the product.

1. Reduce manual product inspection, fixture/product barcode identification function;

2. Equipment parameters, product information upload server, tracking data query system at any time;

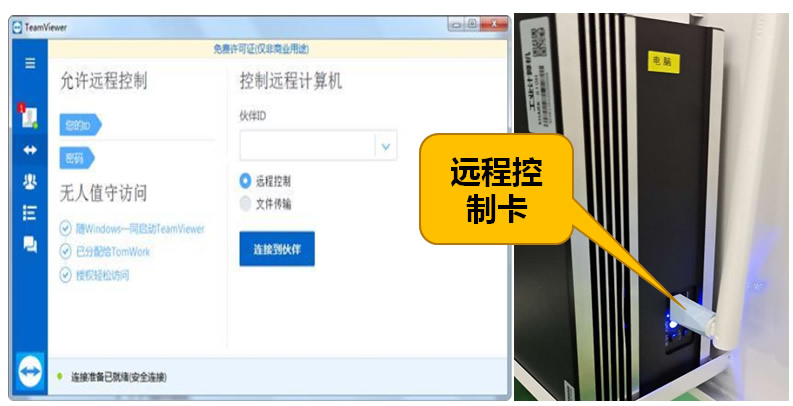

1. Provide customers with stable and smooth professional after-sales dedicated line services;

2. Interconnect IOS between TeamViewer to remotely control each other's desktop with one key;

3. Remote access and remote technical support via the Internet;

4. The remote control software can realize the file transfer between two computers and the operation of one computer to the other computer.

|

1. Using high-speed cutting spindle 60000RPM (imported/domestic optional) stress-free cutting, smooth edge, high precision, with automatic tool break detection function, Z axis with automatic compensation setting, and automatic adjustment of milling cutter depth; 2. 24V high voltage static eliminator; 3. Automatic detection of broken knife. |

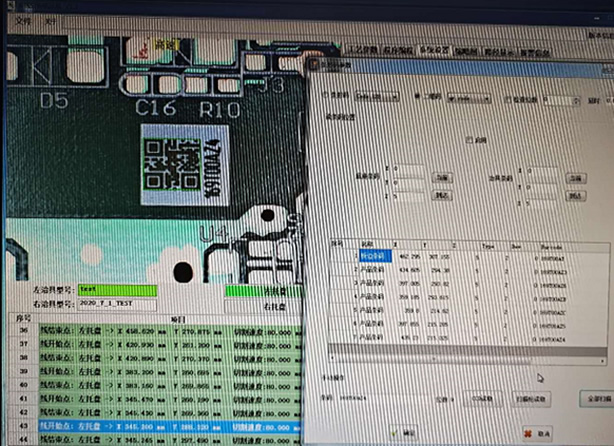

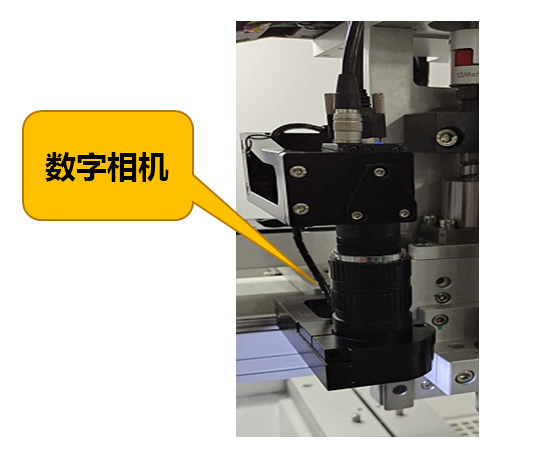

Using WIN7 system operating interface, equipped with high-pixel color digital camera magnification 10 times lens:

Auxiliary program teaching and editing simulation function, the precision is more precise, the image is clearer:

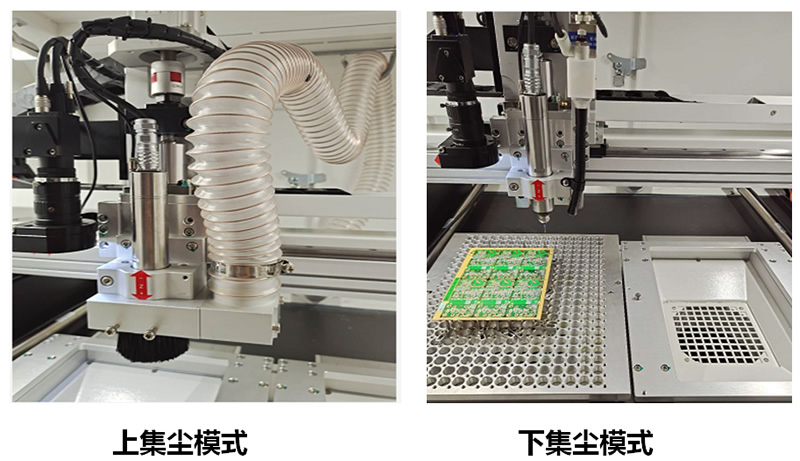

Patented brush design, excellent dust collection; the lower suction structure of the module ensures long-term dust collection effect.

The high-efficiency vacuum cleaner is specially equipped with the lower dust suction and splitting machine, which has super dust removal ability. The lower dust collection method and the unique design of the splitter can effectively deal with the dust generated during the splitting process, which can well protect the cleaning of the product and the workshop The environment and the health of employees.

|

Motor specifications |

3HP 380V 50Hz 3 phase |

|

Output Power |

2.2KW |

|

Suction wind speed |

28 m²/sec |

|

Inhaled air volume |

27 m³/min |

|

Static pressure |

250mm-Ag |

|

Inlet diameter |

160mm |

|

Outlet diameter |

200mm |

|

Noise |

<70dB |

|

net weight |

168Kg |

|

Size |

750*660*1610mm |

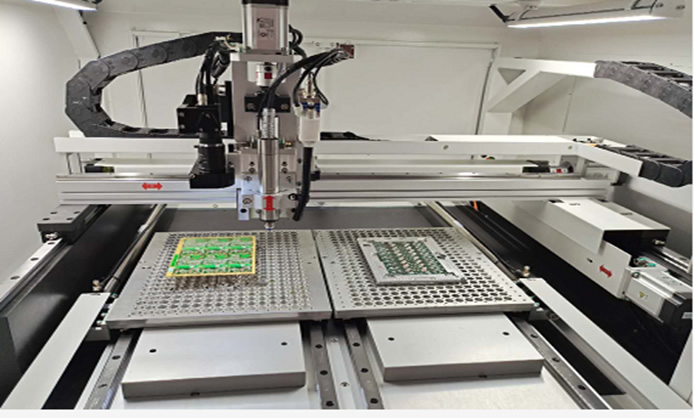

The high-precision grinding screw is used to drive the movement of the working platform to realize the simultaneous high-efficiency work of the X, Y, and Z axes, increase the speed, high efficiency, and high precision of the cutting board, and increase the production capacity.

1: Independent movement, increase production capacity

2: Built-in waste recycling, saving space

3: Simple and convenient maintenance

1: Clear, clear and easy to maintain

2: Bus mode, simple wiring

3: Modular design, quick troubleshooting for maintenance personnel

|

category |

project |

Specifications |

||

|

recognition system |

Automatically find Mark point function |

Color image search and location |

||

|

Video camera |

Color CCD camera, resolution 0.008 mm/pixe (HD) |

|||

|

FOV size |

5mm*5mm |

|||

|

Lighting source |

Ring structure, bright white LED light source |

|||

|

Image processing speed |

Screen processing time |

<200MS/FOV |

||

|

computer system |

Anti-static measures |

Static eliminator, advanced anti-static material bracket, anti-static socket |

||

|

Processable PCB size (MAX) |

L350*W300mm |

|||

|

Cutting accuracy |

± 0.05mm |

|||

|

Machinable PCB thickness/milling cutter |

0.5mm-3.0mm |

|||

|

X, Y, Z platform |

Drive equipment |

Precision Servo Motor Control System / Precision Guide Ball Screw |

||

|

Spindle speed |

High-speed spindle (10000-60000) RPM (imported/domestic optional) |

|||

|

Machine repeatability |

± 0.02mm |

|||

|

Moving speed |

1000 mm/sec (maximum speed) |

|||

Parameter table 2:

|

category |

project |

Specifications |

|

|

Software system |

operating system |

Windows7 |

|

|

Equipment inspection |

Power-on automatic detection function |

||

|

Broken knife detection |

Optional |

||

|

Features |

Can learn processing data through CCD |

||

|

AutoCut program |

Operation interface |

Graphical production of processing data, what you see is what you get |

|

|

Mark |

Points per PCB board |

Up to 2 Mark points can be set |

|

|

Recognition speed |

<0.5 sec/pc |

||

|

Control System |

Computer host |

Dedicated industrial computer |

|

|

Display output |

17' LCD display |

||

|

Other parameters |

equipment weight |

About 600kg |

|

|

power supply |

Host: Voltage AC220V 2ψ50HZ Dust collector: voltage AC380V3ψ50HZ.3P |

||

|

Gas supply |

4-6kg/c㎡ |

||

|

Vacuum method |

Bottom vacuum/upper vacuum optional |

||

|

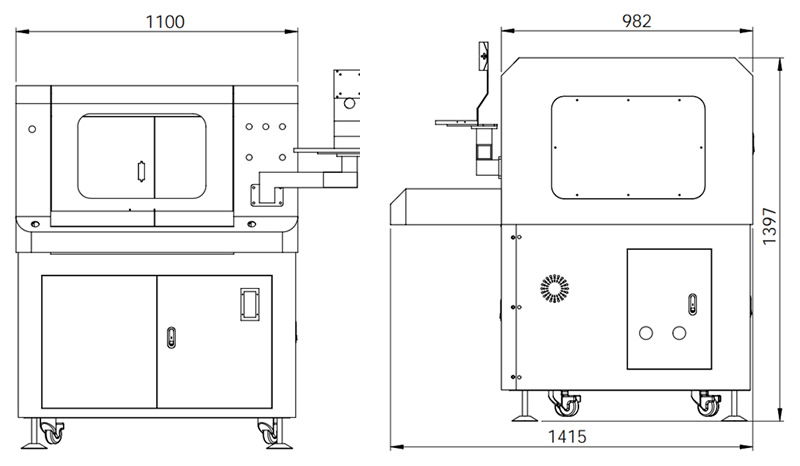

Dimension of Subboard Machine |

L*W*H<=1210X1130X1535mm (not including warning light height) |

||

|

Milling cutter specifications |

0.8-3.0MM (unified tool holder specification 3.175), tungsten steel milling cutter |

||

1. The operation is simple and fast, and the software is intelligent;

2. Small cutting stress, high precision and good stability;

3. Simple structure design, clear layout and easy maintenance

4. Low noise, high efficiency, easy cleaning and maintenance, strong suction and no dust;

5. Geometric patterns such as squares can identify icon points of any shape.

ØIntelligent operation of equipment, ØNo need for professional technicians, ØSmall cutting stress, precise, accurate, stable, ØRealization of industry -4.0, ØTraceability system-MES, ØEquipment remote control

1. Commitment: Warranty period: 1 year, lifetime maintenance. Response time: After receiving the user's notice, professional and technical personnel will not exceed 24 hours (local) and 48 hours (off-site) on-site service to ensure 24-hour uninterrupted after-sales technical service support; repair time: 48 hours.

2. Free warranty: Free warranty during the warranty period, and after the warranty period, spare parts and maintenance services are guaranteed at a reasonable price.

3. Free training: On the day of training, the purchaser’s technical personnel will be trained on the equipment operation for free to ensure that the user’s personnel can be proficient in conventional use methods such as various equipment and software, as well as the judgment and resolution of minor faults.

简体中文

简体中文 English

English Contact us

Contact us