Large manufacturers in the industry choose HUANUO; high standard manufacturing, to meet the stringent technical requirements.

PRODUCTProduct classification

Business consulting

![]()

Product advantages: small space occupation, follow-up dust removal, high-precision visual edge-finding and cutting, DXF import function, automatic tool magazine, broken knife and dropped knife detection, bar code recognition, MES connection.

Today, with the development of modern industry 4.0, electronic products have put forward higher requirements for automated manufacturing. HN-4500 fully automatic online PCB splitter is an automated equipment born for automated production and unmanned chemical factories. HN-4500 board splitting machine is a high-performance, high-precision, small footprint, high-efficiency splitting equipment, with automatic recognition of image mark point alignment, movement track position display tracking, automatic milling cutter segmented cutting functions, production Parameters such as output statistics can be set. Negative pressure follow-up dust removal technology, secondary dust filter dust collection device and static elimination device, completely solve the problem of cutting dust. Automatic feeding and discharging can effectively improve production quality and save labor costs.

Product advantages: small space occupation, follow-up dust removal, high-precision visual edge-finding and cutting, DXF import function, automatic tool magazine, broken knife and dropped knife detection, bar code recognition, MES connection.

12-inch industrial touch screen plus mouse and keyboard, dual operation mode.

Smaller footprint, higher production efficiency.

Tool life display during production and automatic segmented cutting according to the set distance of the tool library (three segments can be set) to extend the tool life. According to the cutting life of the set cutter, the function of automatic cutter replacement is realized. Automatically identify whether there are tools in the tool magazine.

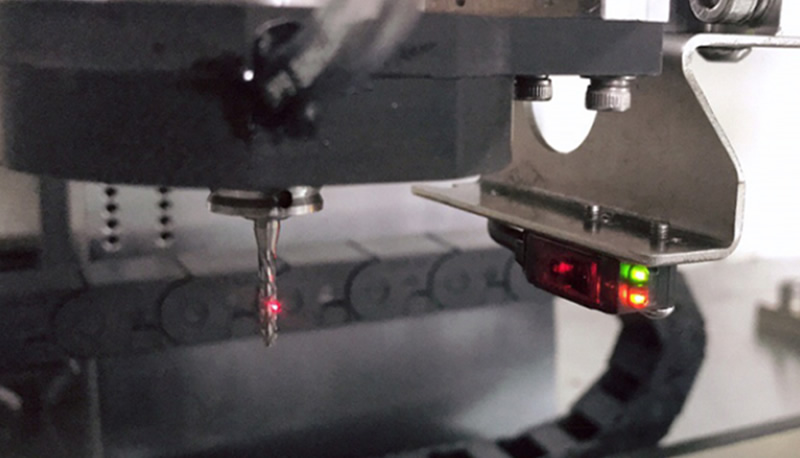

Broken knife and dropped knife detection:

During processing, it can be set to detect every step or every time a piece of PCB is cut to detect whether the tool is broken or slipped, so as to prevent PCB damage caused by the tool slipping in time.

visual system:

It adopts high-pixel digital camera and large magnification lens, which can assist program teaching and editing simulation functions. Automatic MARK positioning correction. The barcode reading function realizes the reading and saving or uploading of 1D/2D barcodes, which is convenient for traceability and digital management.

Mark positioning correction system:

It can make the line change and the replacement of the jig more concise and accurate, and can effectively prevent the board from being placed in place in the production to produce broken products.

The software can do rectangular, copy, translation and rotation, multi-point modification, and quick shape programming with points, straight lines, arcs, circles, curves, squares, etc., which can effectively improve the programming speed of irregular shapes and save programming time.

The file includes new and open processing procedures, and equipment parameter import. The function of opening and creating a program is equivalent to creating a program and opening a program in the program editing interface.

When the parameter is deleted by mistake or lost, the parameter cannot be found, and the software cannot run normally, you can choose to import the backup parameter (or put the backup parameter file in the program running directory and restart the software).

Import DXF program: This function is a CAD import function, that is, offline program design. After drawing the cutting trajectory and Mark position in AutoCAD/UG/CAXA and other drawing software, save it in DXF format, which can be directly imported into the software, saving the time of path teaching with CCD and improving the efficiency of program design.

Dust cleaning cumulative cutting: Set the cumulative cutting distance of the spindle to clean the dust box dust to prevent the dust box from clogging.

The number of sides of the trash can buffer: Set the number of boards that need to be cleaned up when you cut the cumulative number of boards. For the models that do not need to throw the board, you can not use it, just set it to zero.

Follow the "tool setting", "Mark position", "cutting track", "scan code position" (optional), "tool change/pick and place board", and "process parameters" after setting in sequence, click "Save Program" Button to pop up the dialog box shown above. To save the program, you need to enter the secondary password and the name of the new program, and click "OK" after the input is complete. After finishing a processing program, you can check the processing program to confirm whether the current program point is correct.

Use high negative pressure dust removal motor, noise below 75 decibels, use follow-up technology to control the vacuum brush, follow the cutting tool to move at the same speed, keep the best suction position in time, and cooperate with the auxiliary vacuum to efficiently rotate the milling cutter at high speed The dust that is thrown to the PCB board surface and the work table surface is collected and cleaned.

Comparing after 24 hours of cutting, the left is without auxiliary, the right is with upper auxiliary

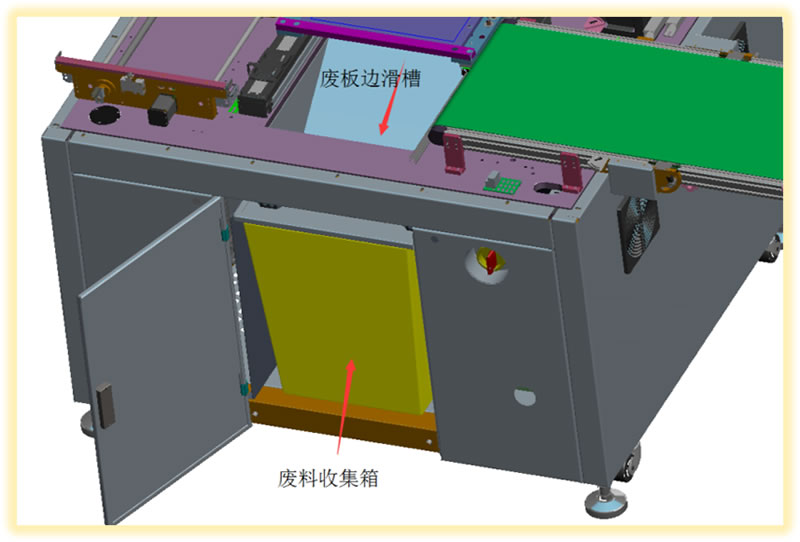

Schematic diagram of waste bin collection:

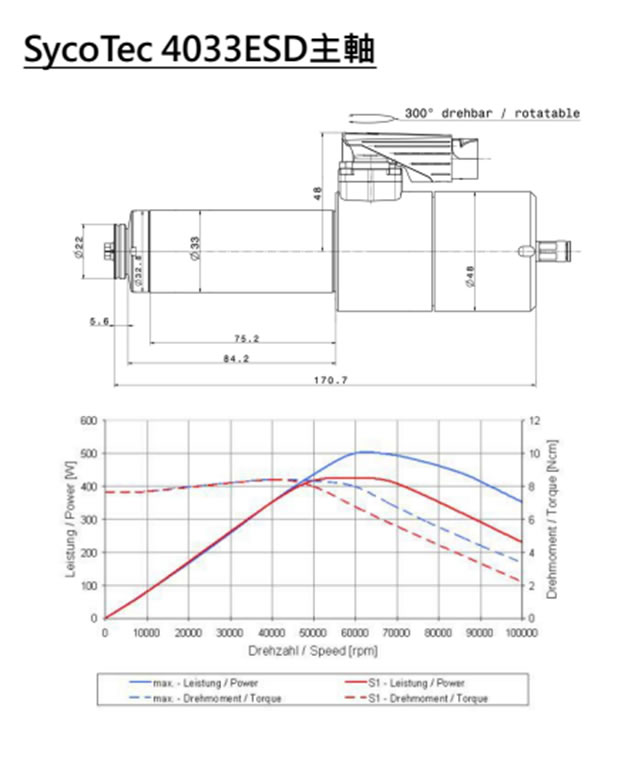

Spindle:

① Spindle opening delay

The spindle that drives the milling cutter to rotate can better cut PCBA of different thicknesses only when it reaches a certain speed. It takes time for the spindle to reach a certain speed. The delay after the spindle is turned on can be set in the user parameters to keep the spindle at the speed. It can be put into cutting work only after normal.

② Spindle maintenance time setting

The spindle is the key core component of PCBA cutting. Correct maintenance and maintenance of the spindle can greatly extend the service life of the spindle. In the continuous working environment, the continuous use time of the spindle can be set, and the spindle maintenance can be carried out after the use time is reached. The spindle maintenance time setting can be a good reminder to the operator.

For the back-end plug-in line, according to the requirements of the production line, it can be connected to the automatic carrier placement machine to realize the automation of the production line, reduce personnel contact with products, improve product quality, and save manpower.

According to the requirements of the production line, the board can be docked with an automatic Tray unloading machine, so that the cut products can be directly placed in the pallet to complete the delivery requirements.

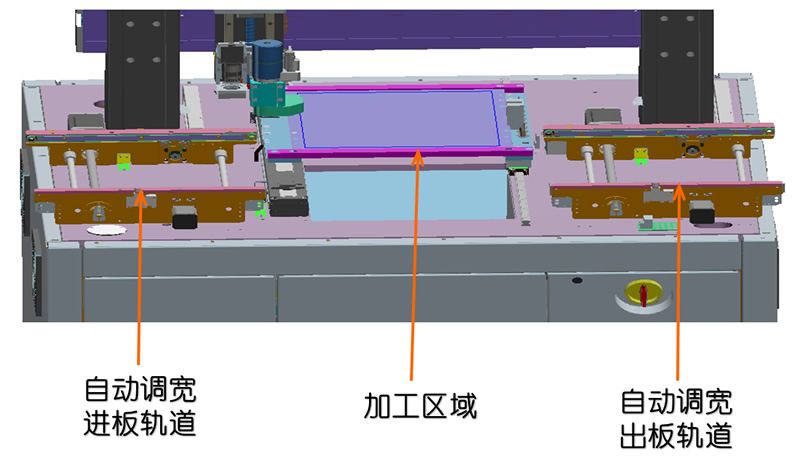

Track in board-track out board

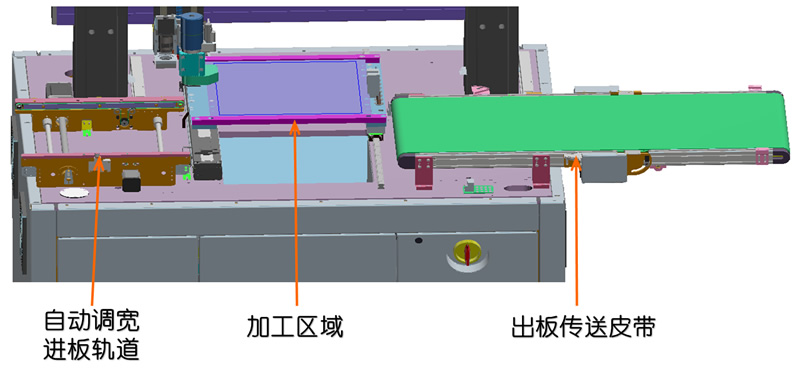

Track in board-belt line out board

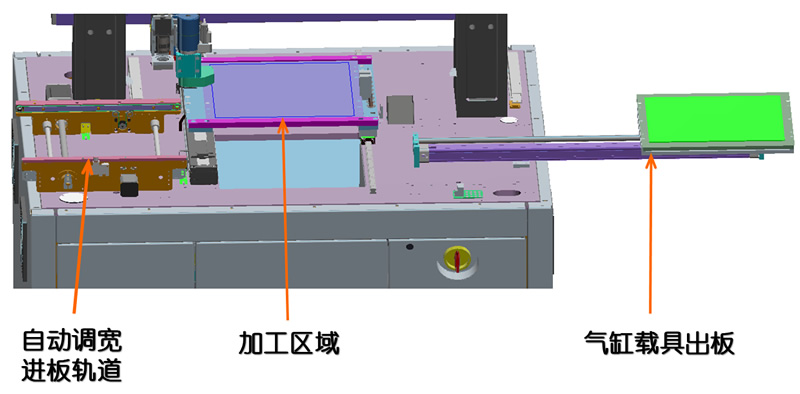

Track inboard-cylinder carrier outboard (and left and right inboard plates can be quickly replaced)

Different devices can be docked according to needs

•Take 10 puzzles as an example: the number of cut points for 10 puzzles is: 68 times 0.6 seconds (the time required to cut one point) plus 2 seconds to shoot the MARK point plus 5 seconds (the time to pick and place the board).

• 68*0.6+2+5=48.8 seconds, one board (10 small boards).

• One-hour production capacity is: 3600 seconds divided by 48.8 seconds≈74 pieces of boards and then multiplied by 10. The production capacity per hour is about 740 pieces, and other related faults are included: 500*0.8=592 pieces.

• So the production capacity is about 600PCS per hour.

1. Commitment: Warranty period: 1 year, lifetime maintenance. Response time: After receiving the user's notice, professional and technical personnel will not exceed 24 hours (local) and 48 hours (off-site) on-site service to ensure 24-hour uninterrupted after-sales technical service support; repair time: 48 hours.

2. Free warranty: Free warranty during the warranty period, and after the warranty period, spare parts and maintenance services are guaranteed at a reasonable price.

3. Free training: On the day of training, the purchaser’s technical personnel will be trained on the equipment operation for free to ensure that the user’s personnel can be proficient in conventional use methods such as various equipment and software, as well as the judgment and resolution of minor faults.

简体中文

简体中文 English

English Contact us

Contact us